AST Working Group (ASTWG)

Accelerated Stress Testing (AST) is a key aspect of the durability assessment of fuel-cells, and AST Development for Heavy-Duty Fuel Cells is a major focus area in M2FCT. To realize this goal more effectively and to accelerate the research output, M2FCT has formed an AST working group (ASTWG) with researchers from National Labs, Academia, and Industry to identify the areas of cooperation and collaboration. Our goal is to strengthen these interactions and expand efforts with researchers from international institutions to promote AST development for fuel cells in heavy-duty applications.

Accelerated Stress Testing (AST) for Heavy-Duty Fuel Cells

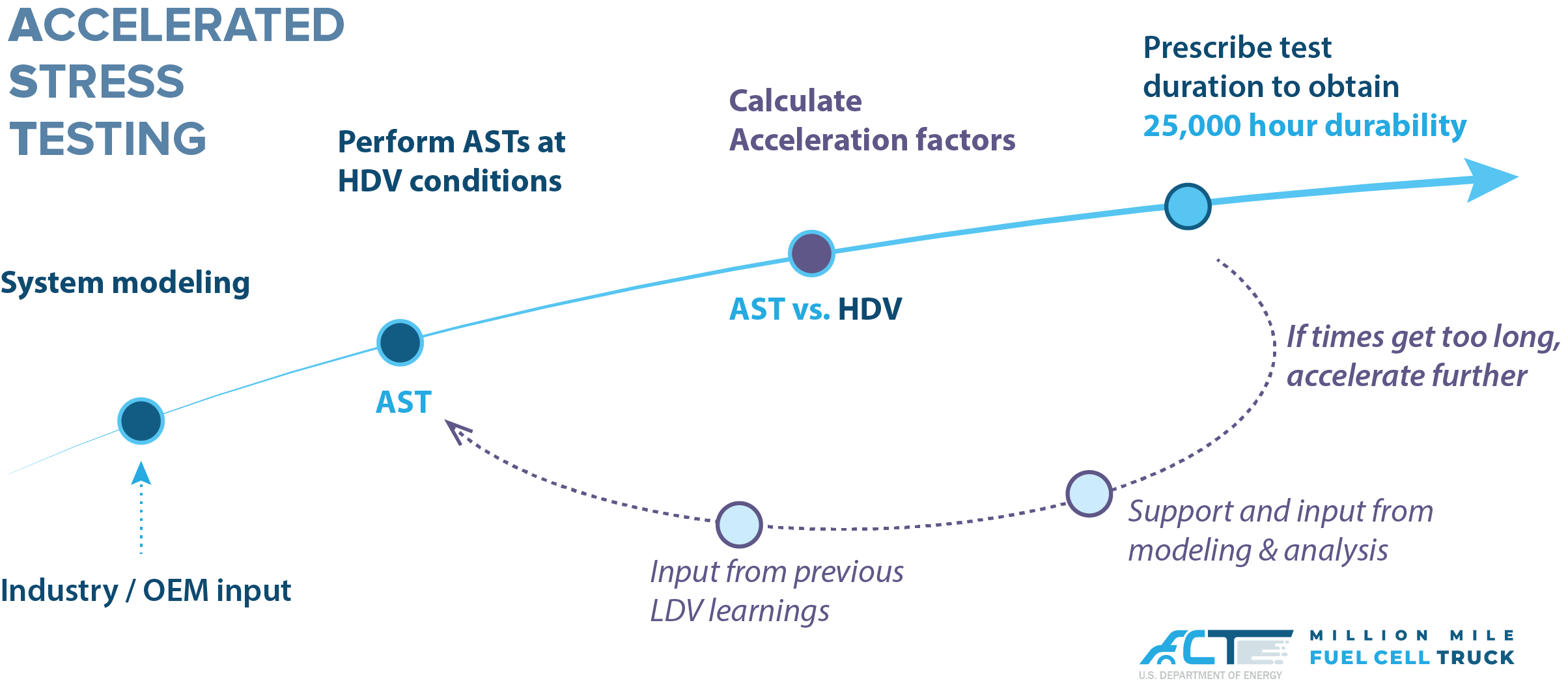

One of the most pressing technical challenges in fuel-cell research and development of HDVs is the greater demand for durability, with 4 to 5x improvements in the lifetime to achieve the M2FCT goal of 1 million miles (1.6 million km). Overcoming this challenge requires not only the design and interrogation of robust materials for more durable cells, but also the durability protocol development and lifetime prediction models to guide the material and cell design. An essential ingredient of durability efforts for fuel cells is the Accelerated Stress Testing (AST) for Heavy-Duty Fuel Cells, which is one of the focus areas and milestones in the M2FCT consortium.

To realize this goal more effectively and to accelerate the research output, M2FCT has formed an AST working group (ASTWG) with the objective of defining the 25,000-hour equivalent AST in the M2FCT 2025 Target.

We have worked closely with the interested stakeholders, received input from the 21st Century Truck Partnership on real drive cycles, evaluated the representative stressors, and developed the following protocol for AST of HDV fuel cells.

Participants and Charter:

DOE & National Labs: LANL, LBNL, NREL, ANL, ORNL

Industry & Academia: 3M, Ballard, Carnegie Mellon, Chemours, Cummins, GM, Nikola, Plug Power, W.L. Gore

ASTWG meets every other month to discuss the current protocols and progress, seek input and feedback from Industry stakeholders and researchers in labs and academia.

International Efforts: We are also working with an International group with representation from the US, EU, Japan and Korea. Learn more...

Resources

Access the ASTWG Resources.